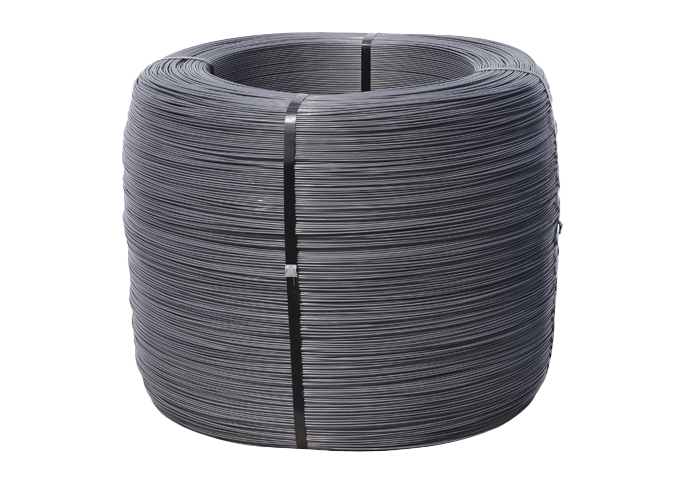

The cold drawing process increases the properties of the wires such as durability, strength, flexibility and smoothness. Cold drawn steel wires are used in many areas with both low and high carbon content.

The cold drawing process increases the properties of the wires such as durability, strength, flexibility and smoothness. Cold drawn steel wires are used in many areas with both low and high carbon content.

Cold drawn steel wire is a material that offers significant advantages in terms of both quality and versatility.

Areas of Use: Nail Production, Automotive, Wire, Straw, Panel Fence, Grill, Shelf, Window Blinds, Packaging of Agricultural Products

| Material | High - Low carbon steel wire |

|---|---|

| Coating | None |

| Wire Diameter | 0.75 mm – 10.00 mm |

| Coating Quantity | None |

| Tensile Strength | 500 - 1900 N/mm2 |

| Coil Weight | 750 - 2000 kg |

| Packing | Badge coil, small coil, Z2-Z3 reels, wooden spool |